Secure Maximum Toughness and Style with Tint Pros Vinyl Wraps Applications

Secure Maximum Toughness and Style with Tint Pros Vinyl Wraps Applications

Blog Article

The Ultimate Overview to Selecting the Right Plastic Covers for Your Job

Picking the ideal vinyl wrap for your job calls for a nuanced understanding of numerous aspects that impact both appearances and capability. From comparing cast and calendared plastic to evaluating the implications of different surfaces, each option brings weight in the total result. In addition, the importance of installment methods can not be forgotten, as correct application is vital for achieving durability and visual appeal - Tint Pros Vinyl Wraps. As you browse these factors to consider, it ends up being clear that the course to a successful vinyl cover job is layered with vital choices that warrant additional exploration.

Sorts Of Vinyl Covers

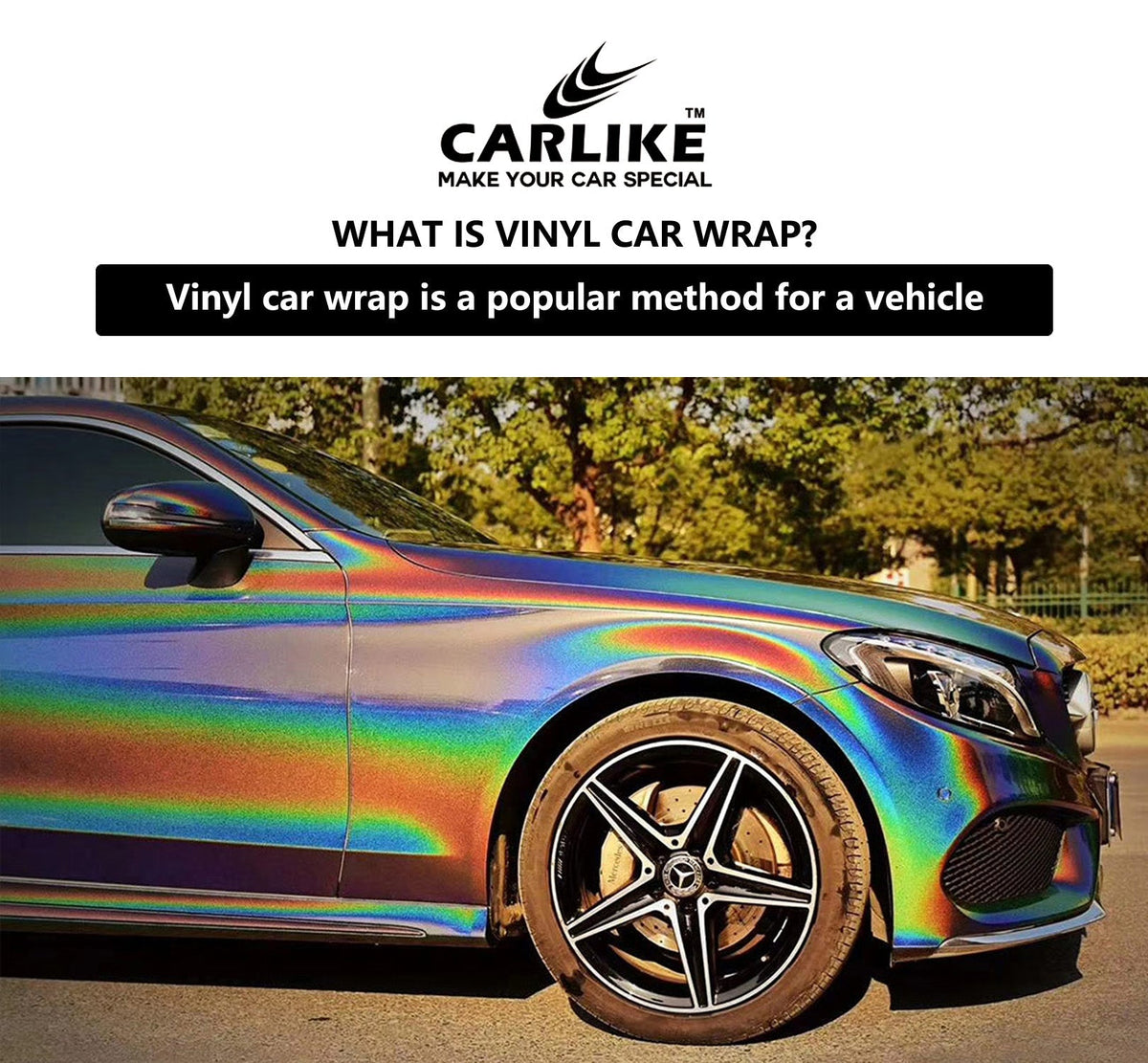

When selecting plastic wraps, recognizing the different kinds readily available is crucial. Vinyl wraps can be broadly categorized into two major kinds: cast vinyl and calendared plastic.

On the various other hand, calendared plastic is manufactured by a process that entails rolling and stretching plastic sheets. This type is typically thicker and less costly than cast vinyl, making it ideal for temporary applications and flat surface areas. While calendared plastic uses an affordable solution, it might not carry out too on detailed layouts or in severe weather problems.

Additionally, specialty vinyl wraps are available, consisting of metallic, matte, and textured coatings, which can boost appearances while supplying unique features. Comprehending these kinds of vinyl covers will allow you to make educated decisions based upon your job needs, making certain ideal cause both appearance and long life.

Selecting the Right Complete

Choosing the proper finish for your plastic wrap is a vital element that can substantially affect the overall visual and capability of your task. Plastic covers can be found in a range of coatings, each offering distinctive aesthetic results and efficiency characteristics. One of the most typical surfaces include gloss, matte, satin, and distinctive choices.

A gloss coating gives a high-shine surface that boosts color vibrancy and deepness, making it excellent for attractive designs. In contrast, a matte surface offers a controlled and innovative look, decreasing glare and blemishes.

Satin surfaces strike a balance between matte and gloss, providing a soft shine that includes elegance without overwhelming the design. Distinctive finishes, such as combed steel or carbon fiber, can add a special tactile aspect, boosting the visual charm of your task.

Inevitably, your choice of surface need to align with the wanted aesthetic and the atmosphere where the cover will be applied. Think about resilience, maintenance, and the particular application to ensure optimal results.

Installation Techniques

Just how can you ensure a perfect application of vinyl covers? The key lies in precise preparation and technique. Begin by cleaning the surface area thoroughly to remove grease, dirt, and wax, as any deposit can endanger adhesion. A clean, smooth surface is necessary for ideal outcomes.

Following, gather essential tools such as a warmth weapon, squeegee, and utility blade. These devices will certainly help in applying the vinyl efficiently and trimming excess material. When using the cover, work in areas, beginning from one edge and gently unrolling the vinyl while utilizing the squeegee to eliminate air bubbles.

Heat can be advantageous in this process; it makes the vinyl much more flexible, allowing it to comply with curves and contours conveniently. Workout perseverance and prevent rushing, as this can lead to misalignment or bubbles. In instances of tough areas, such as around edges or deals with, take into consideration using a technique called "tack and stretch" to develop a smooth fit.

Upkeep Tips

To preserve the integrity and look of plastic covers, regular treatment is important. Start by washing the wrapped surface area with a gentle soap solution and a soft sponge or microfiber towel. Prevent rough chemicals, as they can damage the vinyl. Tint Pros Vinyl Wraps. It's finest to clean your cover every 2 weeks to eliminate dirt, crud, and contaminants that can cause the cover to lose its gloss.

Dry the surface thoroughly after washing, as water spots can become long-term if entrusted to dry normally. For included security, take into consideration applying a specialized plastic wrap sealer, which can help maintain the color and protect against fading from UV direct exposure.

Additionally, avoid parking in straight sunlight for prolonged durations, as prolonged exposure can bring about staining and destruction of the wrap. Utilize an automobile cover or park in shaded areas. if check this possible.

Regularly inspect the cover for any kind of indications of lifting or damages. Resolve them without delay to stop additional degeneration if you notice any kind of problems. Complying with these upkeep suggestions will certainly guarantee that your vinyl cover stays vivid and prolongs its lifespan, eventually improving the looks of your project.

Usual Mistakes to Stay Clear Of

When it pertains to vinyl wraps, preventing common risks can significantly impact both the application process and the long life of the wrap. One constant error is disregarding surface area prep work. Correct cleansing and priming are important to make sure that the vinyl adheres successfully. Any type of dust, oil, or old adhesive can bring about early lifting or bubbling.

Another usual mistake is selecting the incorrect sort of vinyl for the details application. Different projects call for various materials; for instance, an automobile wrap must make use of cast vinyl for longevity, while a short-lived sign may be sufficiently offered by calendared vinyl.

Insufficient heat application during setup can likewise cause problems such as wrinkles and improper adherence. Utilizing a heat weapon at the correct temperature level is essential for dealing with the vinyl, specifically in tough locations like sides or contours.

Lastly, neglecting post-installation treatment can reduce the life expectancy of the wrap. Failing to comply with upkeep guidelines, such as avoiding extreme chemicals or rough cleansing tools, can cause damage. By guiding clear of these errors, you can boost the efficiency and visual appeal of your plastic wrap job.

Verdict

In final thought, selecting the appropriate vinyl wrap requires mindful consideration of numerous variables, including the kind of plastic, surface alternatives, and installation methods. Appropriate preparation and adherence to best techniques are essential for accomplishing optimum results and guaranteeing the long life of the cover. By avoiding common risks and making notified choices, individuals can successfully enhance the aesthetic appeal and durability of their tasks via the strategic usage of vinyl wraps.

Plastic wraps can be extensively classified right into 2 primary types: cast vinyl and calendared vinyl.On the various other hand, calendared vinyl is made by a process that entails rolling and stretching plastic sheets.Selecting the ideal finish for your vinyl cover you can try here is a crucial element that can considerably impact the general visual and capability of your project.When it comes to plastic covers, avoiding common risks can dramatically influence both the application procedure and the durability of the cover.In final thought, choosing the ideal plastic cover necessitates cautious consideration of various variables, consisting of the type of vinyl, coating choices, he has a good point and installation techniques.

Report this page